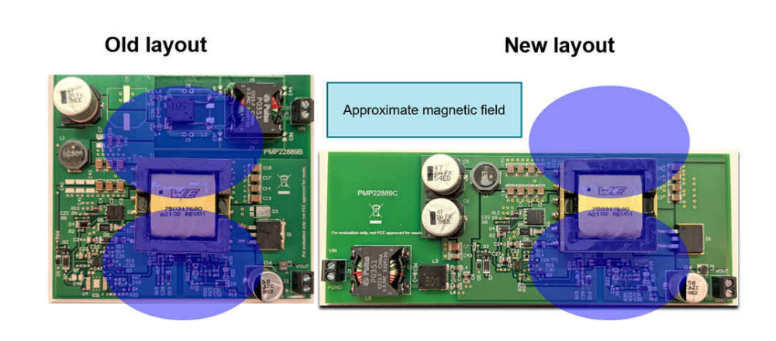

Another way to reduce coupling between the inductor and output capacitors is to use 𝗮 𝗳𝘂𝗹𝗹𝘆 𝘀𝗵𝗶𝗲𝗹𝗱𝗲𝗱 𝗶𝗻𝗱𝘂𝗰𝘁𝗼𝗿. You can see in the image on the top right how a molded ferrite case ensures almost no magnetic field escapes. These types of components allow for more layout options.

𝗧𝗵𝗲 𝗹𝗼𝘄𝗲𝗿 𝗴𝗿𝗮𝗽𝗵 𝘀𝗵𝗼𝘄𝘀 𝘁𝗵𝗲 𝗺𝗮𝗴𝗻𝗲𝘁𝗶𝗰 𝗿𝗮𝗱𝗶𝗮𝘁𝗶𝗼𝗻 𝗳𝗿𝗼𝗺 𝗮𝗻 𝗲𝗾𝘂𝗶𝘃𝗮𝗹𝗲𝗻𝘁 𝘂𝗻𝘀𝗵𝗶𝗲𝗹𝗱𝗲𝗱, 𝘀𝗲𝗺𝗶-𝘀𝗵𝗶𝗲𝗹𝗱𝗲𝗱, 𝗮𝗻𝗱 𝗳𝘂𝗹𝗹𝘆 𝘀𝗵𝗶𝗲𝗹𝗱𝗲𝗱 𝗶𝗻𝗱𝘂𝗰𝘁𝗼𝗿. You can see that there is not much difference between the black trace for unshielded and the red trace for semi-shielded– perhaps five dB of improvement. Whereas the equivalent fully shielded inductor trace in blue gives a region of 30b lower magnetic field leakage.

👉 Another tip is at the 𝘀𝘁𝗮𝗿𝘁 𝗼𝗳 𝘁𝗵𝗲 𝘄𝗶𝗻𝗱𝗶𝗻𝗴, often marked with a dot or bar, is the end of the inductor, which 𝘀𝗵𝗼𝘂𝗹𝗱 𝗯𝗲 𝗰𝗼𝗻𝗻𝗲𝗰𝘁𝗲𝗱 𝘁𝗼 𝘁𝗵𝗲 𝘀𝘄𝗶𝘁𝗰𝗵 𝗻𝗼𝗱𝗲. That is because the start of the winding is buried in the centre of the inductor. And there’s a certain amount of self-shielding effect from the outer windings connected to the DC output.

👉 It is good practice 𝘁𝗼 𝗵𝗮𝘃𝗲 𝗮 𝗴𝗿𝗼𝘂𝗻𝗱 𝗽𝗹𝗮𝗻𝗲 𝘂𝗻𝗱𝗲𝗿 𝘁𝗵𝗲 𝗶𝗻𝗱𝘂𝗰𝘁𝗼𝗿 as this will have an electric fielding shielding benefits. This will not do much for magnetic field however. The skin depth of copper at typical switching frequencies would mean an unreasonable thickness of material to provide magnetic shielding.